Optimize

with the

Optimization Engine

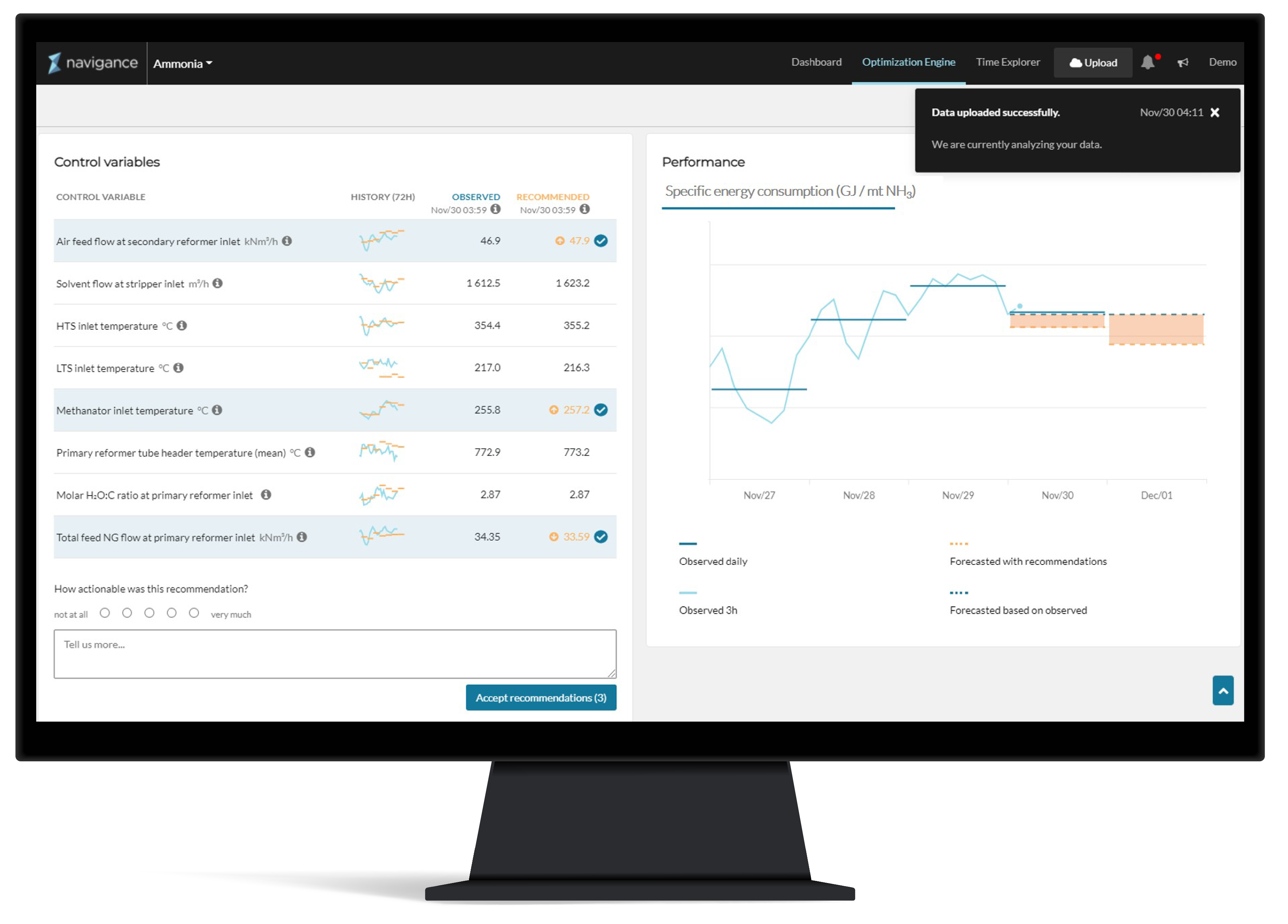

Keep hitting critical goals and KPIs around the clock. Our hybrid process models and industrial AI scan your plant data and deliver automatic, actionable recommendations for fine-tuning process control variables.

Take actions. Optimize with confidence.

The Navigance Optimization Engine is cloud-based Software as a Service (SaaS) that delivers automated recommendations plus insights from our own experts to help you continuously optimize plant performance.

- A dynamic, highly adaptable hybrid model of your chemical process

- 24/7 optimization recommendations in a custom web interface

How the Optimization Engine benefits you

Find opportunities to optimize your chemical process automatically and continuously.

Select your optimization goals – from efficiency to output, energy consumption to cost of production.

We'll integrate them into a hybrid model of your plant and create a strategy for achieving them.

Don't waste hours analyzing your process data for ways to optimize.

The Navigance Optimization Engine does it for you, providing automatic recommendations you can follow with confidence.

Use its actionable advice to fine-tune your process control variables and keep hitting critical KPIs.

And adapt quickly to different scenarios and objectives, with high levels of flexibility built in.

A single, intuitive dashboard shows your key process data and all recommended actions.

Customize it with the insights you need most. And share access securely with those who need it.

The Navigance Optimization Engine needs little in-house resource.

Our experts assist your team not only with planning and deployment of your solution, they provide ongoing advice and insights too.

We protect your sensitive data at every stage with ISO-certified, end-to end encryption.

That’s reinforced with 24/7 threat monitoring and your own strict controls over who has access.

How the Navigance Optimization Engine works

Our cloud-based analytics tools and expert insights keep your chemical process running at its optimum. Here’s how.

Implementation tailored to you

Optimizing should free up not tie up your team. Our experts implement it right, so you can enjoy the benefits.

Download your free implementation guide

Get the Navigance guide to implementing continuous process optimization – and take your chemical operations to the next level.

What our customers say

“Implementing the recommendations to our process has become a daily routine for our shift operators. They can take actions quickly since we use the Navigance dashboard on a screen right next to our DCS screens. Already, after a few weeks, we have noticed an improvement in our plant’s performance."

“Through implementing the recommendations generated by the Optimization Engine I can continuously improve my plant’s performance. Using the web-based interface provides me the flexibility to follow the plant operation closely and analyze process data easily, even when working from home.”

Explore further. Discover more.

Handy tools, useful reads and upcoming events related to our Optimization Engine. Helping you to optimize your chemical process.