Process optimization with AI - Opportunities and limitations of applying machine learning for optimization of syngas plants

37th Nitrogen+Syngas Conference | 2024

AI-based Process Optimization in Syngas Plants

This technical paper presents a joint case study by INEOS, Clariant, and Navigance, showcasing how AI-based tools, hybrid models, and digital collaboration platforms are transforming process optimization in syngas plants.

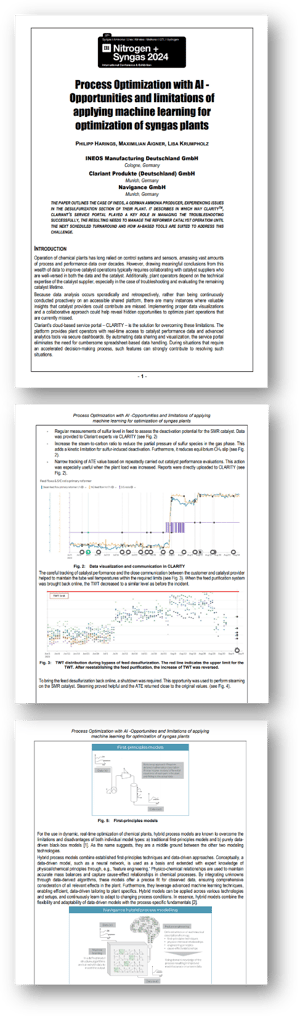

The study focuses on an incident at INEOS’s ammonia plant in Germany, where a mechanical failure in the feed desulfurization section threatened catalyst performance. Using CLARITY™, Clariant's digital service portal on the Navigance cloud-based platform, the plant team and Clariant experts collaborated in real-time to mitigate damage and monitor catalyst health. Through digital dashboards and automated data exchange, the platform enabled rapid decision-making and continuous expert support during a critical operational phase.

To facilitate long-term decision making and assess catalyst lifetime risks, Navigance has developed in collaboration with Clariant hybrid AI models combining first-principles modelling with machine learning. These models support strategic evaluation of catalyst operations and turnaround planning and are offered as two advanced tools in an easy-to-use web-based interface:

- Interactive Reformer Optimization Tool: A plant-specific, web-based model enabling operators to simulate “what-if” process changes and predict their impact on key reformer KPIs.

- Catalyst Performance Projection Tool: Integrated into CLARITY™ Prime, it lets engineers forecast catalyst behavior under different operating conditions, using high-resolution, real-time data.

The paper highlights both the power and limitations of AI-based models in real-world applications. While data quality and training periods remain key factors, the approach significantly reduces reliance on manual simulations and improves operational agility.

These tools are offered as software-as-a-service and represent a leap forward in accessible, scalable optimization for ammonia, methanol, and hydrogen producers.

Fill out the form below to access your free download of this paper.

- A download link will be available right after you submit the form.

- We’ll also email the file to the address you provide.

OUR RELATED SOLUTIONS

Unlock the full potential of your chemical plant with our integrated analytics platform. Leverage advanced process and data science expertise to drive process optimization with intuitive tools for your plant team. Benefit from cloud-based services designed to support digital transformation at every stage.

Clariant’s AI-powered digital service for optimized catalyst operation.

Visit Clariant website to learn more